With years of experience in system integrations, including expertise in connectivity, Industrial Internet of Things, data architecture and software platforms, today we specialize in data collection, analysis and visualization to help manufacturers improve efficiency and profitability.

Our mission is to provide the client with a unique application for intelligent production analytics of the new generation with ready-made functions for instant realization of its value, a tool for improving the efficiency of production processes and equipment, saving energy and optimizing energy costs, reducing the cost of products and services.

Our technology stack integrates advanced real-world analytics, including machine learning and artificial intelligence technologies, to generate insights that improve asset, machine and line utilization, reliability, quality and production flexibility.

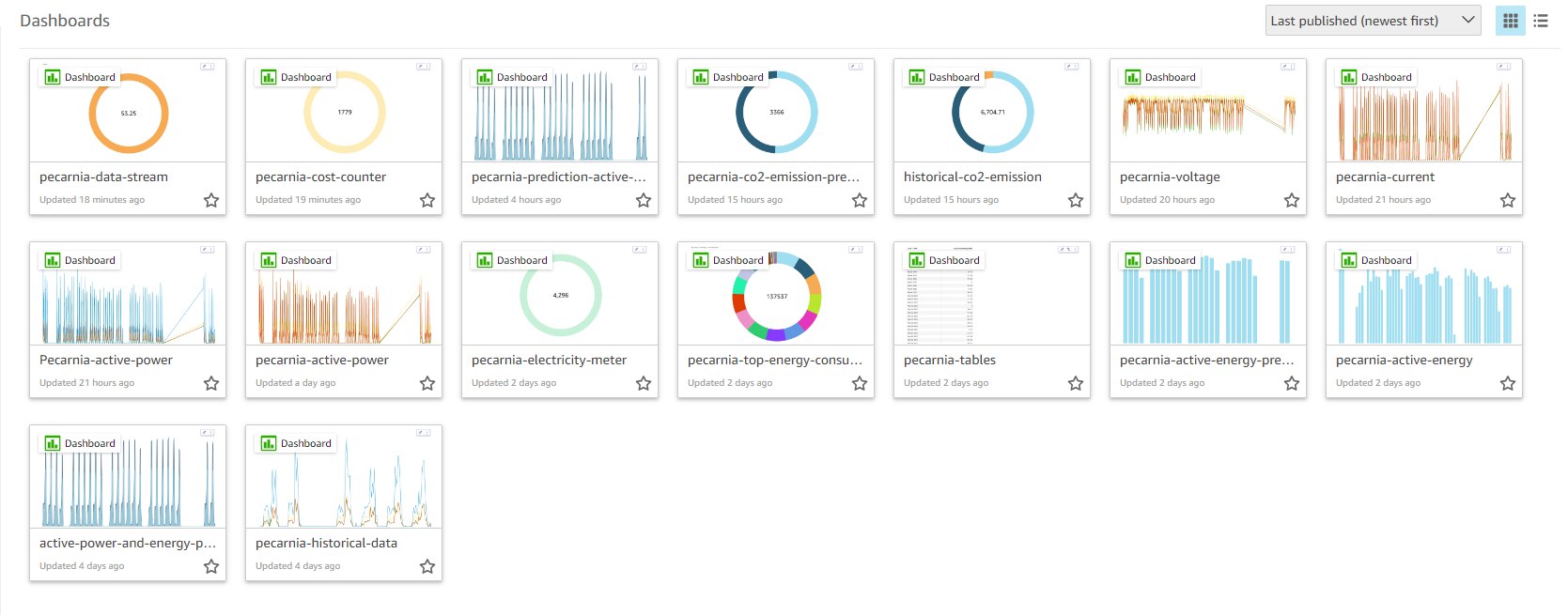

The application generates ready-made and customizable reports, reports, instructions and recommendations to optimize the performance of machines and lines. We are able to predict and reduce equipment downtime and answer the questions “what happened?”, “why did it happen?”, “what to do so that it doesn’t happen!”.

We provide practical reports and analysis that help answer the specific problems that exist in manufacturing plants related to the operation of machines, production lines, industrial infrastructure equipment, processes, logistics. We have expanded the offer of analysis, starting with the analysis of electricity, gas, heat, water, compressed air consumption, tariff, losses, the possibility of reducing consumption.

Here are some examples of our satisfied clients:

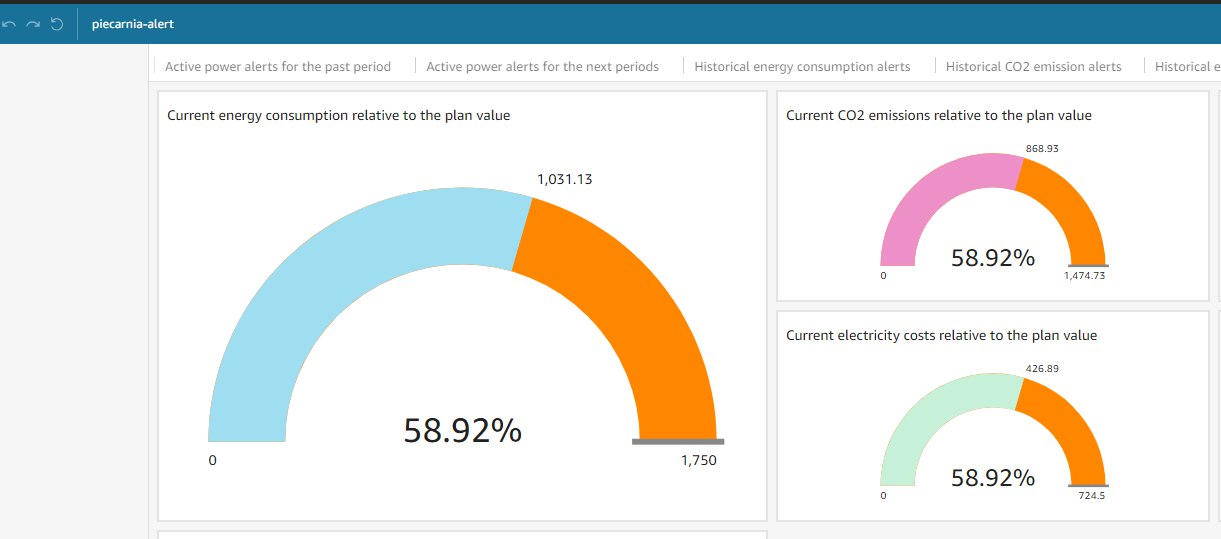

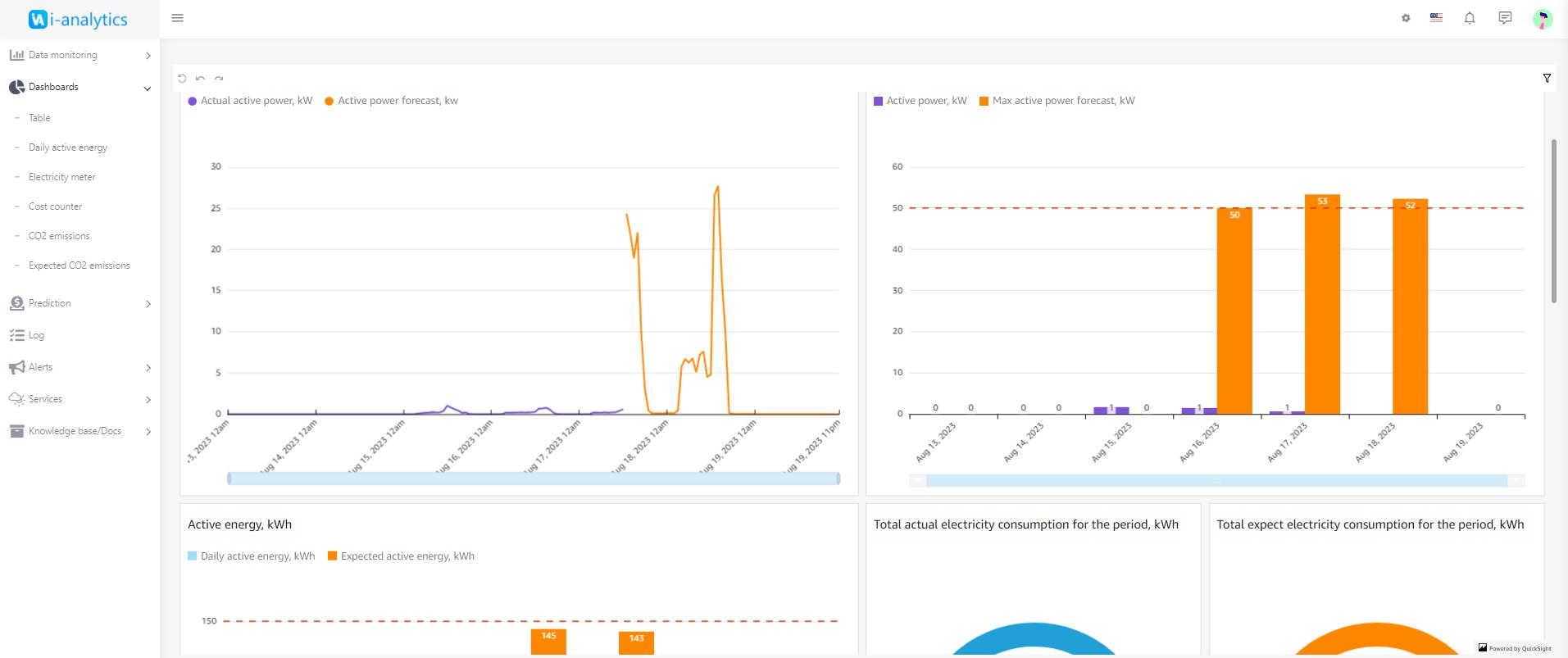

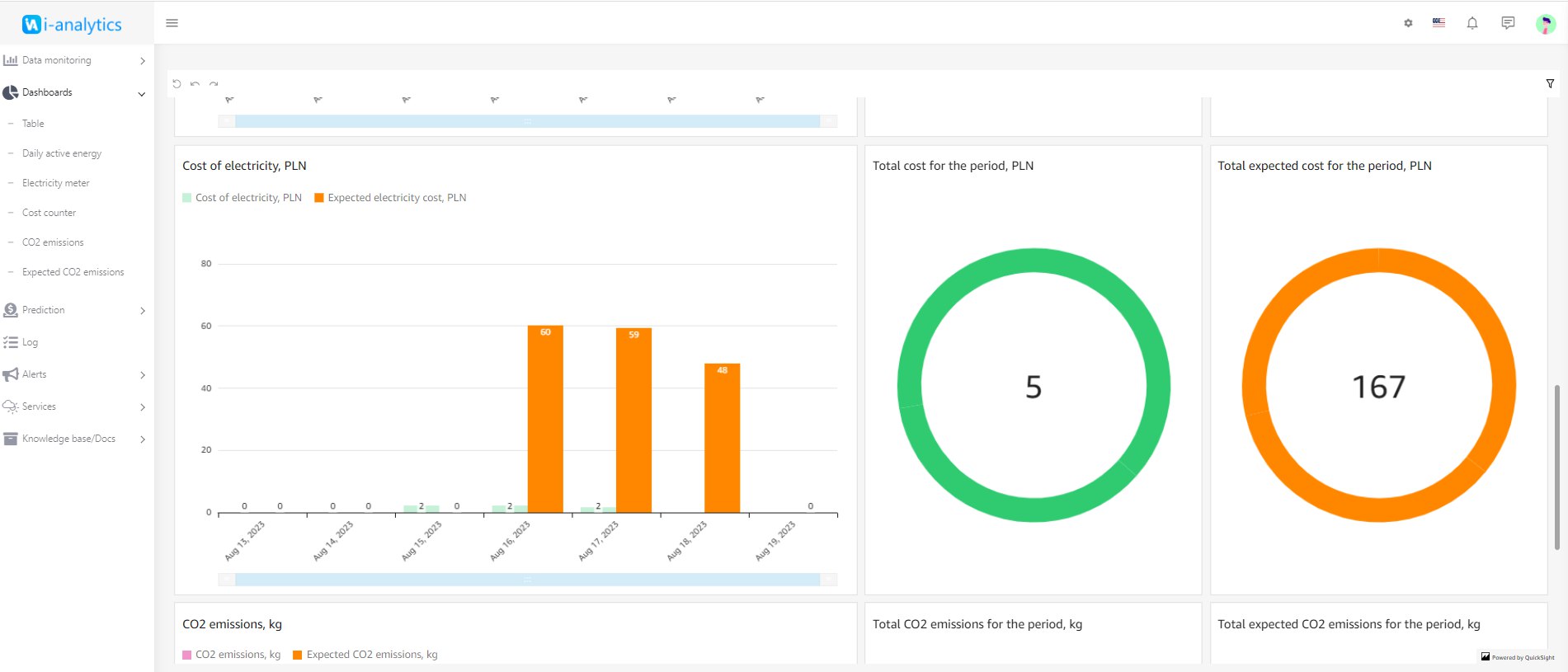

High-quality online monitoring of parameters of energy resources and equipment.

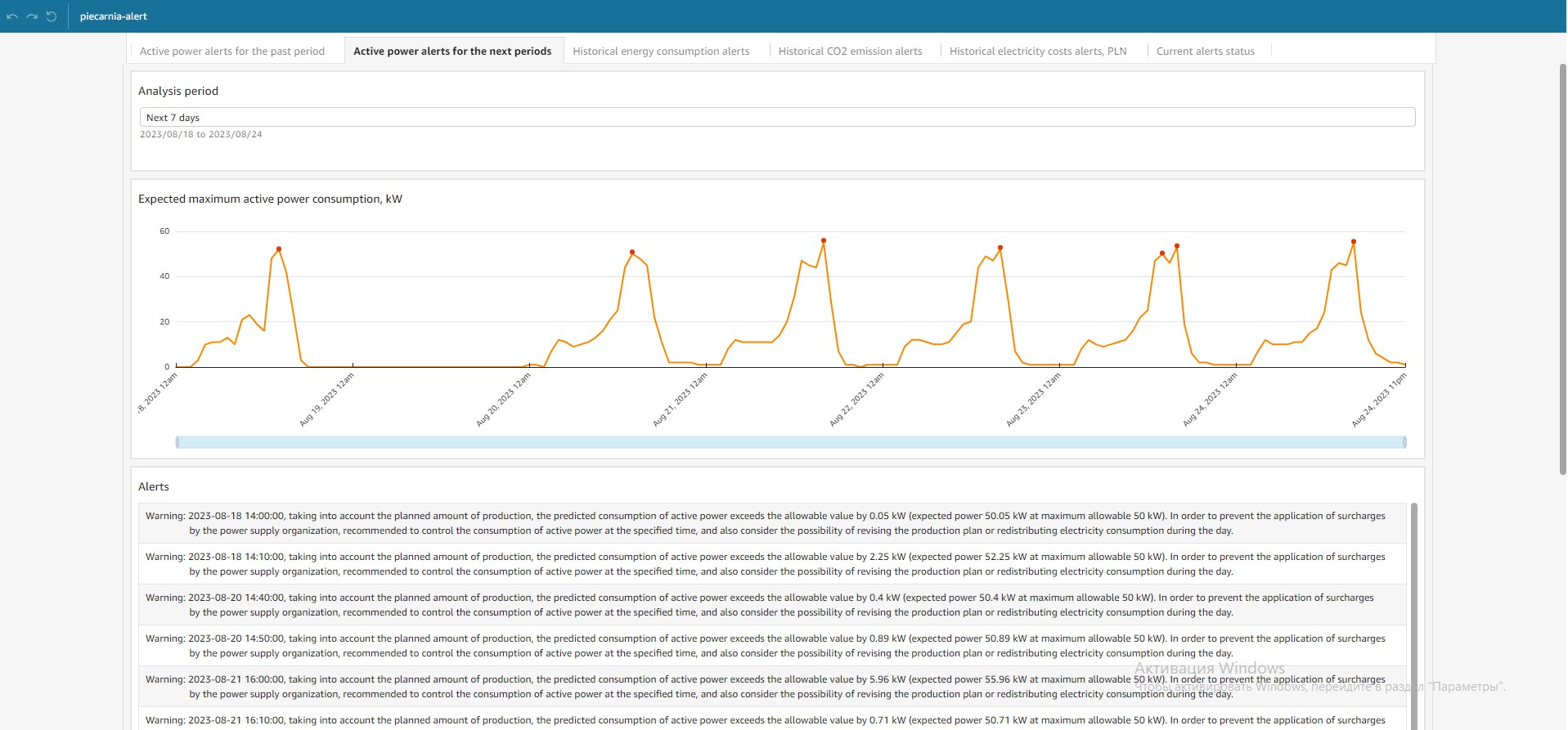

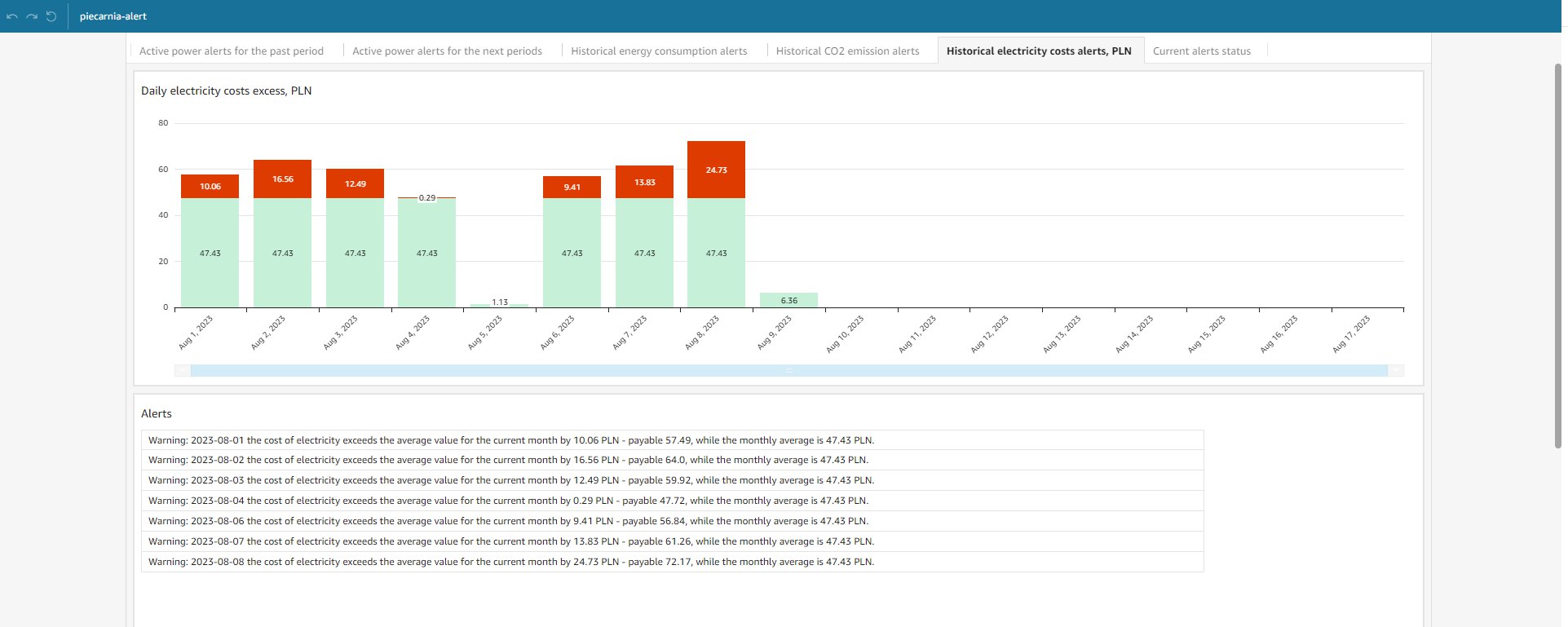

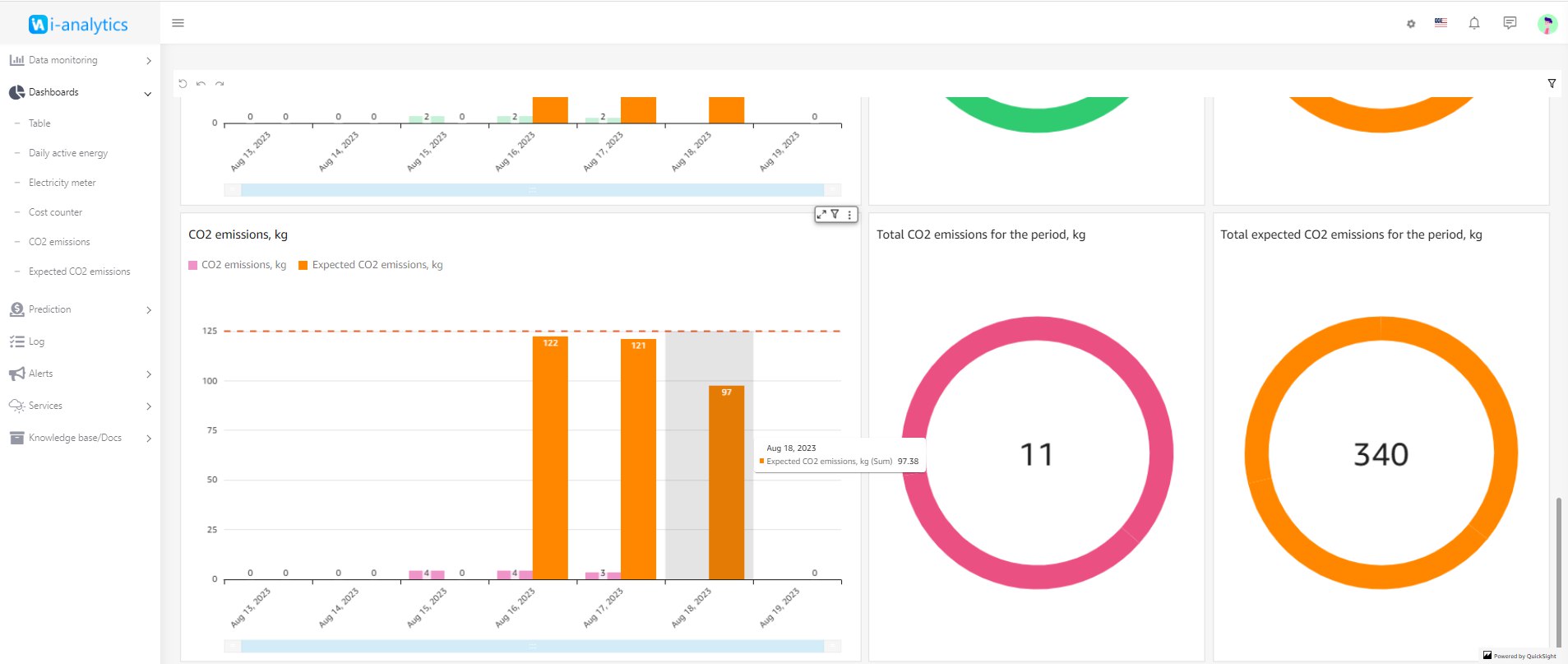

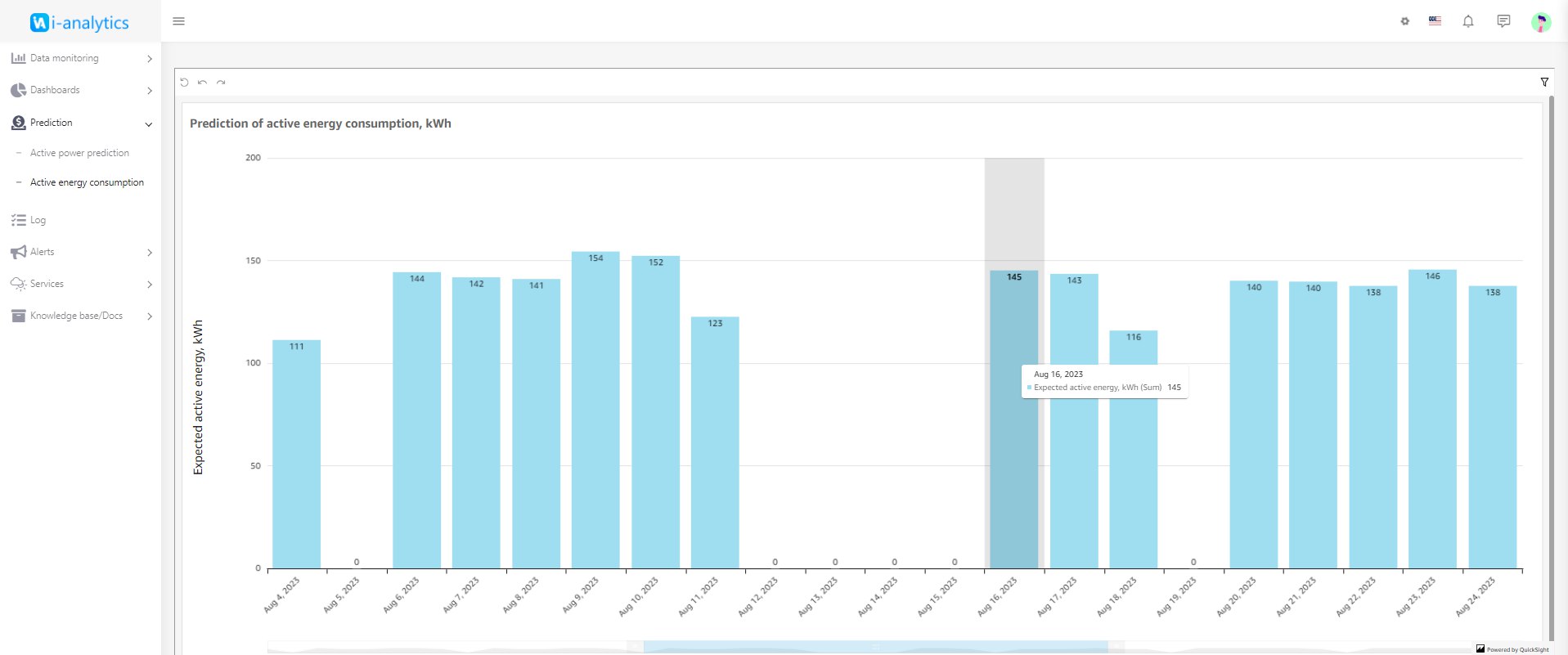

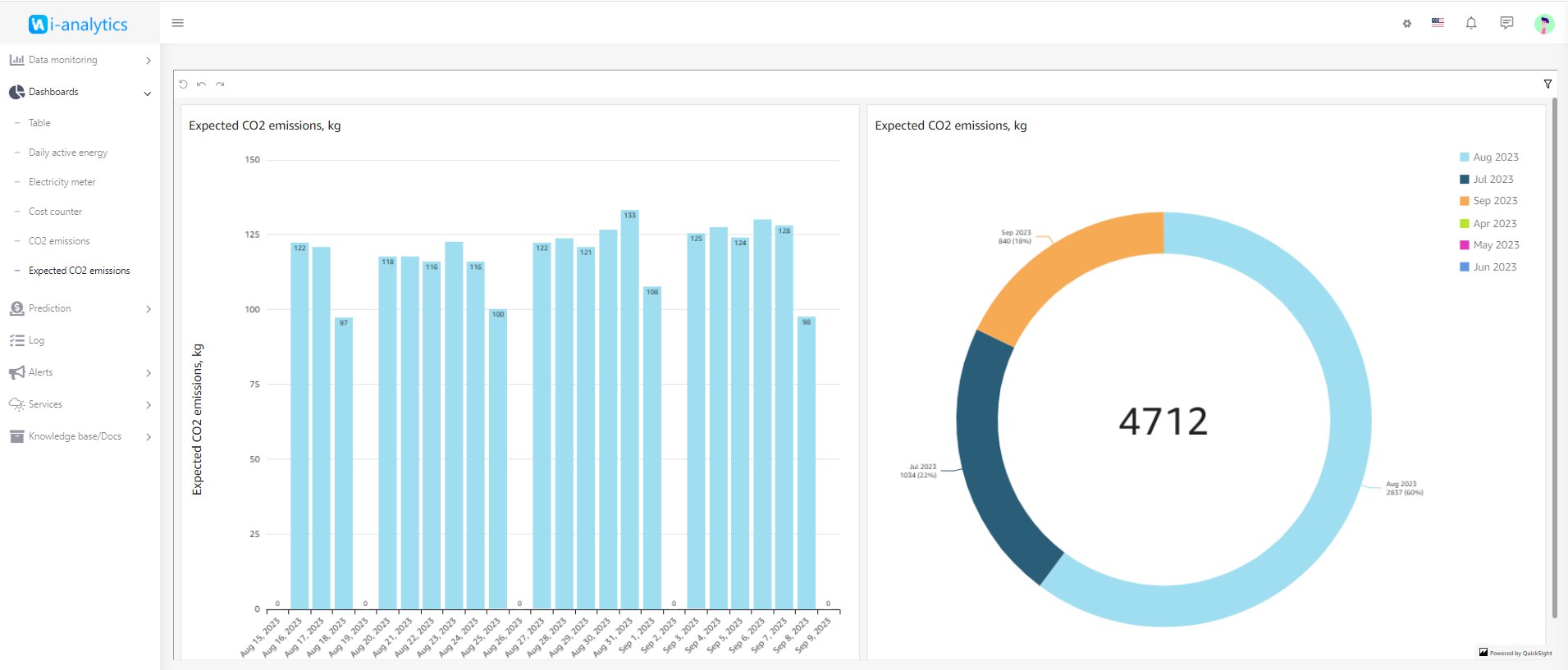

Predicting production loads and energy costs, as well as caring for the environment and reducing emissions

Anomaly Analysis and Intelligent Alert System, Reports and Recommendations